Exactly How Mass Containers Can Improve Effectiveness in Your Packaging Workflow

Bulk containers play a necessary function in enhancing product packaging operations. Their layout enables far better use of upright room and promotes arranged stock management. This performance brings about minimized material replenishment regularity and lower labor costs. Furthermore, the sturdiness of these containers minimizes item damage. As services seek ways to boost their processes, recognizing the multifaceted advantages of bulk containers comes to be important. What other advantages might they give the table?

Streamlined Storage Solutions

As business seek to enhance their operations, structured storage space solutions have actually ended up being important for improving product packaging efficiency. Effective storage space not only conserves room but likewise facilitates quicker accessibility to materials, which is vital in busy production settings. Bulk containers, developed for easy stacking and company, considerably reduce the complexity of storage space systems. They allow services to take full advantage of upright room while reducing the footprint needed for inventory.

Furthermore, these containers usually include ergonomic designs that simplify taking care of and transport, reducing the risk of injury and improving workflow. By combining products wholesale containers, companies can decrease the frequency of restocking and improve their supply chain procedures. Overall, the implementation of efficient storage solutions promotes a much more organized workspace, causing increased productivity and decreased operational expenses. Via thoughtful design and strategic usage of bulk containers, services can achieve significant improvements in their product packaging operations.

Waste Decrease and Sustainability

While the quest of efficiency usually drives packaging decisions, waste reduction and sustainability have emerged as important factors to consider in modern-day operations. Business increasingly acknowledge that embracing mass containers can greatly reduce product waste. These containers usually make use of less product packaging product than typical approaches, causing a smaller carbon footprint.

Mass containers can be recycled multiple times, which further decreases the demand for single-use packaging and decreases overall waste getting in landfills. Their style commonly permits for less complicated recycling procedures, lining up with sustainability objectives.

In addition, business that prioritize waste reduction can boost their brand name online reputation, appealing to environmentally conscious customers. By implementing bulk containers, businesses not only simplify procedures however additionally add favorably to environmental stewardship. This dual benefit of functional effectiveness and sustainability placements business favorably in an affordable market significantly concentrated on green techniques.

Boosted Setting Up Line Effectiveness

Applying mass containers on assembly lines greatly improves performance by streamlining the handling and transport of materials. By making use of bulk containers, producers can lower the frequency of product replenishment, enabling workers to concentrate on setting up tasks as opposed to consistent supply management. This causes fewer interruptions and a smoother process, inevitably boosting performance.

Furthermore, bulk containers are developed for simple assimilation with automated systems, even more optimizing the setting up process. Their standard sizes and shapes help with far better organization, enabling workers to situate and gain access to products promptly. This reduction in search time adds to a much more fluid manufacturing my response setting.

Price Savings and Enhanced Earnings Margins

Remarkable expense savings can be realized through the fostering of bulk containers in product packaging procedures. By minimizing the demand for several smaller plans, business can lower material expenses especially. Mass containers typically require less product packaging product on the whole, resulting in reduced expenses on supplies. In addition, the efficiency of bulk handling lessens labor prices related to packing and unpacking, even more boosting financial savings.

Less trips to distributors and reduced transportation expenses are additionally key advantages, as bulk containers permit increased product capability per shipment. This higher volume not only lowers shipping expenditures yet additionally maximizes storage room within facilities, bring about improved supply management.

The toughness of mass containers frequently converts to decrease damage helpful site prices throughout handling and transport, protecting item honesty and minimizing waste. Collectively, these factors add to better revenue margins, making bulk containers an economically useful choice for companies seeking effectiveness in their product packaging operations.

Adaptability Throughout Industries

Bulk containers supply impressive adaptability across various industries, making them an important asset past just cost savings. In the food and beverage field, these containers assist in the risk-free transport and storage space of huge quantities of ingredients, boosting efficiency in manufacturing lines. In pharmaceuticals, mass containers guarantee conformity with strict health criteria while accommodating the bulk handling of basic materials. The chemical industry likewise advantages, as these containers hold up against extreme compounds and avoid contamination, sustaining secure operations. used plastic containers. Furthermore, the farming field utilizes bulk containers for carrying fertilizers and grains, minimizing and enhancing logistics waste. Their flexibility reaches production, where mass containers improve assembly processes and lower the demand for excessive packaging. This cross-industry capability not only improves operational effectiveness however additionally advertises sustainability via decreased packaging waste, showing the indispensable role bulk containers play in modern supply chains

Frequently Asked Concerns

Exactly How Do Bulk Containers Influence Employee Security in Packaging Procedures?

Bulk containers substantially boost staff member security in packaging procedures by lowering hand-operated handling, lessening injury risks, and promoting ergonomic techniques. Their style assists in much safer transportation and storage, ultimately developing a much more safe and secure workplace for all employees.

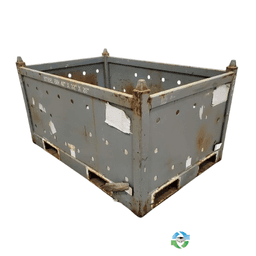

What Materials Are Bulk Containers Typically Made From?

Mass containers are typically made from resilient products such as high-density polyethylene, metal, polypropylene, or timber - used collapsible containers. These products provide stamina, resistance to environmental variables, and viability for various components, guaranteeing effective and secure transportation of products

Can Bulk Containers Be Personalized for Details Products?

Yes, bulk containers can be tailored for particular products. Producers often customize measurements, products, and features to fulfill special requirements, making certain perfect protection and effectiveness throughout storage and transport of different goods.

Exactly How Do Mass Containers Affect Transport Logistics?

Mass containers enhance transportation logistics by maximizing cargo area, lowering the variety of journeys needed, and decreasing taking care of prices (refurbished bulk containers). Their standard dimensions help with reliable filling and unloading, eventually leading to enhanced operational performance throughout the supply chain

What Is the Life-span of Bulk Containers in Regular Usage?

The life expectancy of bulk containers in normal usage typically varies from 5 to 10 years, depending upon worldly top quality, Bonuses taking care of practices, and environmental conditions. Proper maintenance can significantly expand their functionality and performance.

Executing bulk containers on setting up lines considerably enhances efficiency by simplifying the handling and transport of products. Bulk containers frequently need much less packaging material in general, resulting in lower expenditures on supplies. In pharmaceuticals, mass containers ensure compliance with rigid health criteria while accommodating the mass handling of raw products. Their versatility prolongs to manufacturing, where bulk containers simplify setting up processes and lower the requirement for extreme packaging. Mass containers substantially improve worker safety and security in packaging operations by decreasing hands-on handling, decreasing injury risks, and promoting ergonomic methods.